Site Designed By: www.viziongraphics.com

|

P.O. Box 310600 1 Cascade Pointe Dr. SW Atlanta, Georgia 30331 404-437-3703 Tel 404-696-1808 Fax |

Q. What is engineered hardwood flooring?

A. Engineered hardwood flooring is a product made up of a core of hardwood, plywood or HDF and a top layer of hardwood veneer that is glued on the top surface of the core and is available in almost any hardwood species. The product thus has the natural characteristics of the selected wood species as opposed to a photographic layer. The “engineered” product has been designed to provide greater stability, particularly where moisture or heat pose problems for solid hardwood floors.

Q. What is the difference between a laminate, solid hardwood and an engineered hardwood floor?

A. Laminate- core of product is typically made of High Density Fiber (HDF). The top layer is a photographic layer that should appear identical to the product it replicates, be it wood, vinyl, tile, etc. The product is generally 3/8” thick and is a floating install with tongue and groove glue less locking system which allows you to install and uninstall the floor several times if desired. This product is typically the least expensive. Solid Hardwood- the product is the solid natural wood species throughout the entire piece of flooring, typically with a tongue and groove installation. Good sanding and refinishing capabilities. The product is typically more expensive and has some limitations as to where it can be installed due to moisture issues.

Q. What does greater stability mean?

A. The instability of solid hardwood is usually moisture or heat related. Under adverse conditions, solid hardwood floors can warp, cup, swell or split apart. Engineered hardwood flooring overcomes these problems by constructing a multiple-ply plank which counteracts twisting and remains flat and intact. This makes engineered hardwood flooring a better choice for installation over radiant heat sources, over concrete whether it’s below grade or above, and in rainy climates.

Q. How many layers does engineered flooring have?

A. In addition to the top hardwood veneer, engineered wood flooring typically has three or more core layers. Of course, there is greater stability with more layers. The core layers may be plywood, high density fiberboard, or hardwood. For example, Vanier engineered flooring has five to seven hardwood core layers.

Q. Does engineering destroy the natural beauty of hardwood floors?

A. Not at all. The top hardwood layer is the same genuine hardwood you have in solid hardwood floors. This “show” veneer is available in most species of natural hardwood.

Q. What is the thickness of the hardwood veneer?

A. The hardwood veneer, or top layer of hardwood, can typically be 0.6mm to 4.5mm or more in thickness. A quality hardwood veneer will provide many years of wear. For example, Vanier engineered hardwood flooring has a Select and Better 2mm hardwood veneer and comes with a 25-year finish warranty.

Q. Can I refinish an engineered floor?

A. It depends upon the thickness of your hardwood layer but the fact is that 95 % of hardwood surfaces are never refinished. With the high quality finishes that are offered and the extensive process that refinishing a floor entails, damaged areas are often removed professionally. If sanding is desired, typically, the professional sanding procedure removes 1/32 of an inch. Thus if your floor has a 2mm layer you can sand the floor 1-2 times.

Q. Besides different species, what else accounts for the different appearances in hardwoods?

A. Hardwood veneers have the same surface appearances as solid hardwood flooring because they’re both natural hardwoods. Different appearances result from the different ways the hardwood are sawn. The different sawing methods are: i) Flat Sawn or Plain Sawn, ii) Rotary Cut, iii) Off-Set Rotary Cut, and iv) Sliced Cut.

Flat Sawn (also referred to as plain sawn) - can be flat grain (which has a cathedral or gothic effect) or vertical grain (which has a radial or edge grain effect).

Rotary Cut – method of cutting wood in which the hardwood layer is peeled off the log using large wood lathes. This peeling method shows dramatic, wilder graining.

Off-Set Rotary Cut – method of cutting wood which gives a sliced appearance and grain pattern with the added cross grain stability of sliced, without the sliced cost. Hardwoods are more dimensionally stable across the grain, and off-set rotary cutting takes advantage of this property. The yield is lower than a regular rotary cut creating a slight price increase vs. standard rotary.

Sliced Cut – method of cutting wood in which the hardwood layer is sawn like regular lumber. This shows method finer graining.

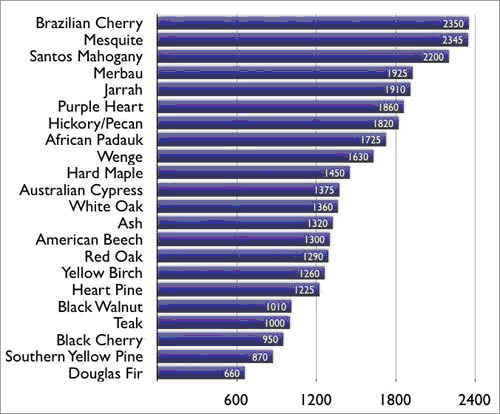

Q. What is the Janka hardness test and why should I be aware of it as a consumer?

A. As a consumer of quality wood flooring, you naturally want to know how the product you are thinking about purchasing will withstand wearing and dents. The Janka hardness rating is your standard measurement for this purpose. The Janka test is conducted by measuring the force needed to lodge a .444-inch steel ball in the wood species to a depth of half the ball's diameter. The higher the rating, the harder is the species of wood. Of course, the Janka hardness rating is also useful when assessing how easy or difficult it is to hammer a nail into the hardwood or cut it with a saw.

Janka Hardness Chart:

Q. Is the Janka rating useful for engineered hardwood flooring?

A. The Janka rating is a good one to keep in mind for engineered hardwood flooring as well as solid hardwood, especially if durability is a key selling feature for you. The Janka hardness rating of the hardwood used for the veneer on your engineered flooring will guide you to the best choice for your intended flooring use. Vanier Hard Maple, Brazilian Cherry and Hand-scraped Oak, Red Oak, and Black-Stained White Oak are all excellent engineered floors for high traffic areas.

Q. How many times can you sand a floor?

A. As per the NOFMA calculations, the sanding operation should remove no more than 1/32”. You should thus be able to sand a 1/16” hardwood layer on an engineered floor 1-2 times if correctly done. It is not recommended to sand a 1/32” thick hardwood layer. Solid wood floors can only be sanded to 1/32” above the tongue to maintain the stability of the tongue and groove joint.

Q. In preparing a sub-floor, what is the maximum variance you should allow?

A. The preparation of your sub floor is a key factor to the final outcome of your floor. You should have no more than ¼” over 8’ variance on your sub floor.

Q. Do I have to be a contractor to buy from CTR?

A. No. Anyone who meets the minimum order requirement can buy from CTR. This means that whether you are a distributor, retailer, or a homeowner with a big project, you can take advantage of the great pricing that CTR offers.

Q. Does CTR ship worldwide?

A. Yes.

Q. How are residential deliveries made?

A. The product would be delivered on a truck equipped with a lift-gate. The pallets would be lowered to the ground and pulled onto your driveway with a pallet-jack. A residential delivery is considered completed once the product is placed on the driveway. Building materials are heavy and will require proper equipment or labor to accept goods on delivery. Please check the weight of your goods before they are delivered so that you are properly prepared.

Q. What is your warranty policy?

A. Our engineered products have either a 20 year or 25 year manufacturers finish warranty depending on the product. You should contact us immediately if you were to have a warranty issue. Upon verification that it is a warranty issue we would replace the product.